Case: O/G Decarb - reducing CO2 emissions from offshore oil and gas production

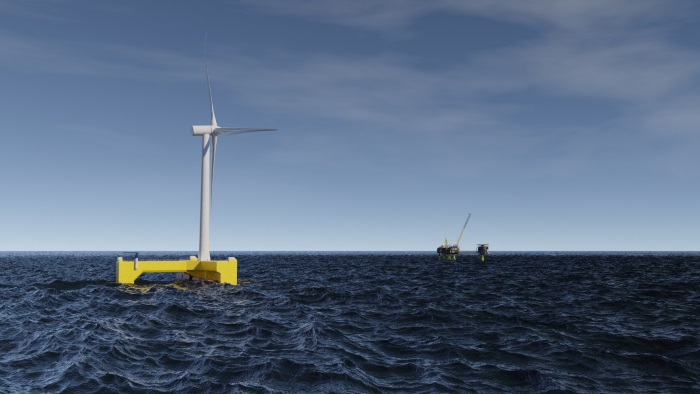

A study of an innovative project based on Power-to-X and floating wind technology shows that CO2 emissions from production of offshore oil and gas can be reduced significantly, if the platforms are supplied with renewable energy. The solution can potentially bring greener gas to shore.

The project O/G Decarb is a theoretical feasibility study, where the project partners during the past two years have assessed whether wind and wave energy on a floating foundation with optional integration of hydrogen, potentially can improve the CO2 emission from offshore oil and gas production.

The project partners are Floating Power Plant, Hydrogen Valley, DTU Wind Energy, TechnipFMC, Total, and DTU Offshore. Energy Cluster Denmark has facilitated the study.

Conclusions from the study

The conclusions show that floating wind and wave technology has great technical potential in regards to reducing emissions from offshore oil and gas production. However, there is limited commercial potential and scalability in the Danish North Sea due to the special conditions that applies to Danish operations; mature fields and a low water depth combined with limited wind and wave energy compared to other locations.

In the study, three concepts and business cases have been elucidated in order to reduce the footprint from production of oil and gas.

- The study has shown a potential for an offshore production platform to be supplied with energy from wind and waves. This in itself could potentially reduce CO2 emissions from production by 70 percent.

- The study has also shown that integration of hydrogen production and storage can be used as an alternative energy source on days with little or no wind or waves. This significantly improves the power consistency and reduces CO2 emissions by more than 70 percent.

- The study also highlighted the possibility of adding 2-15% hydrogen to the natural gas exported to land. Hydrogen in the natural gas export stream can reduce the footprint of the gas produced, which has proved technically possible but is limited by the current legislation.

- Due to the characteristics of the Danish North Sea, the specific project application will result in high reduction costs. In another operating environment, the technology has a clear potential in terms of providing a cost-effective solution for delivering consistent energy production, which will provide maximum CO2 reduction.