CO₂ Storage

The CO2 storage team at DTU Offshore brings together researchers and industry experts to advance efficient carbon storage, which is essential towards reaching national climate goals.

With 50+ years of Danish subsurface knowledge, strong industry ties, and cross-disciplinary collaboration, we deliver practical solutions to the challenges of CO2 storage.

We combine experiments and modelling to assist the evaluation of storage sites and develop geophysical tools and sensors to assess risks and monitor leakage.

Our mission is to bridge research and practice to ensure reliable and scalable CO2 storage for Denmark and beyond.

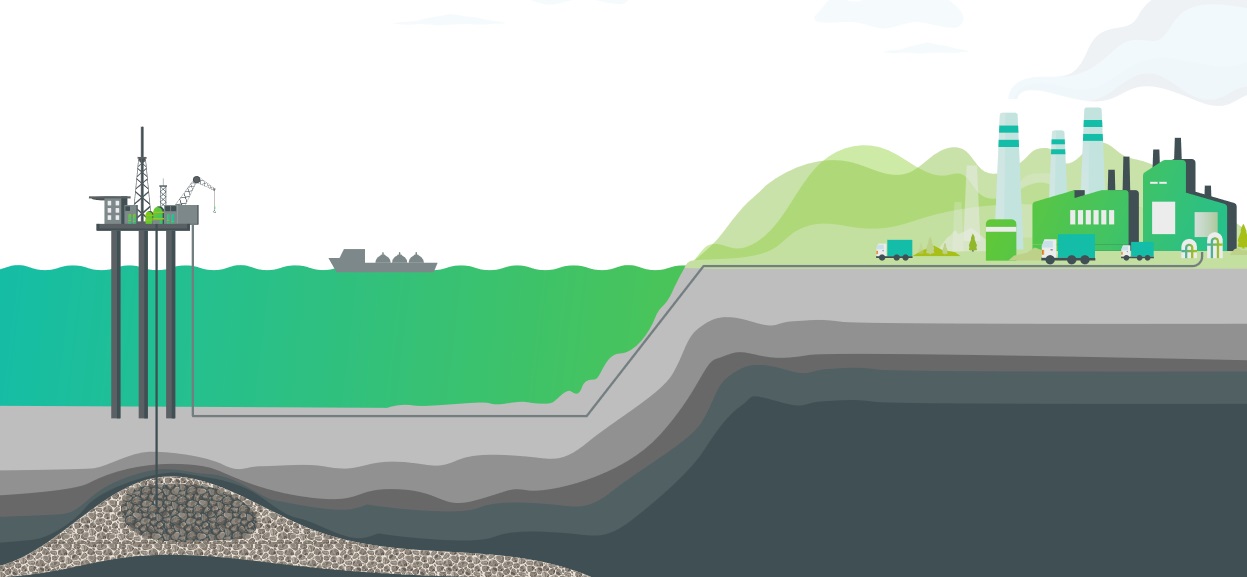

Climate change is a serious global challenge, and one way to address this challenge is by storing CO2 in the subsurface. This will make the road to Net Zero Emission shorter, and it holds great potential for implementing Net Minus strategies.

DTU Offshore leverages deep knowledge of the Danish North Sea subsurface and infrastructure to help make Denmark a European CO2 storage hub. Achieving this goal demands research, technology development, and a strong focus on the full value chain and upscaling.

Our CO2 storage research was launched in 2021 and is already delivering promising results. Through a range of projects, we aim to ensure that subsurface CO2 storage is both safe and cost-effective

- CO2 containment projects focus on analysing reservoir integrity during CO2 injection, developing advanced monitoring sensors and systems, and understanding environmental impact in the unlikely event of a leak.

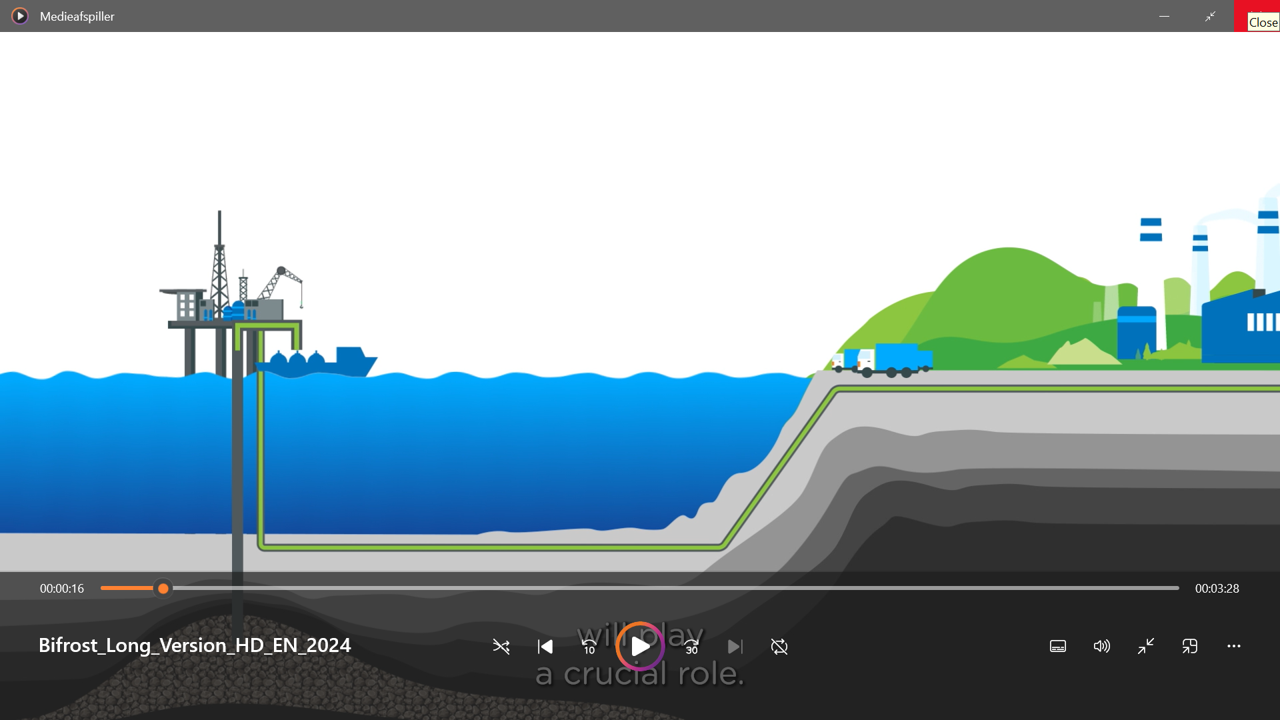

- The EUDP-funded Project Bifrost, with DTU Offshore as the academic partner, explores chalk reservoirs for CO2 storage and develops monitoring technologies. The project demonstrated CO2 injection into the depleted Harald West (sandstone) and Harald East (chalk) gas fields, reusing the existing Harald infrastructure.

The existing oil and gas fields provide an opportunity to accelerate the permanent storage of CO2 thanks to:

- A well-described reservoir storage capacity

- Decades of accumulated knowledge of the subsurface, both static and dynamic

- A reservoir seal which has been proven to be gas tight over geological time

- Potential to re-use infrastructures

- Long distance to shore and inhabited areas

Also revisiting relinquished exploration licenses and understanding the failing mechanism for categorised dry holes is seen as an excellent opportunity to open up additional storage capacity.

Many Danish oil and gas fields are chalk reservoirs, and questions have been raised regarding their suitability for CO2 storage - particularly regarding rock dissolution and mechanical integrity.

To assess the suitability of chalk reservoirs for CO2 storage, a series of research projects has investigated potential showstoppers - none were found. Overall, the conclusion of the project was that chalk reservoirs are at the same CO2 storage maturity level as sandstone reservoirs.

One of the main challenges when re-using existing oil and gas fields for CO2 storage is the integrity of existing well penetrations, which might result in potential leak paths if the well barriers are breached after abandonment. This is a concern as the wells and some of the abandonment barriers were designed and installed before CO2 storage was considered.

Cement is the main barrier element in the abandoned wells, and this barrier may be affected if exposed to CO2. Based on both experiments and modelling, research is creating an understanding of the impact of CO2 on barrier integrity.

Using shale as a barrier material for the wells will ensure integrity over geological time. Researchers are investigating where naturally occurring shales can form part of a well barrier and thereby ensure long term integrity. The swelling capabilities will also be tested within a CO2 environment.

When evaluating a potential storage site, it is essential to evaluate not only the potential for leakage from abandoned wells, but also to verify the integrity of the cap rock.

Researchers have developed a modelling tool, the DFM tool, which can evaluate the potential for fracture propagation in the caprock during the injection period. The purpose is to assist flow modelling in naturally fractured reservoirs by improving the characterisation and prediction of the fractures. Flow through fractures is modelled either by modifying the bulk rock properties to take account of the fracture porosity and permeability, or by generating Discrete Fracture Network models (DFNs).

In both cases, a more accurate representation of the distribution, orientation, length and connectivity of the fractures will give a better history match. Traditional fracture modifiers and DFNs are generated stochastically – fractures are placed at random, and there is little constraint on length and connectivity. Therefore, they often give poor results.

Instead, we built fracture models by simulating the nucleation and growth of the fractures, based on subcritical fracture propagation and linear elastic fracture mechanics theory. We therefore generate much more realistic fracture models which honour geology.

Get more insights

There is a growing need for more accurate, realistic storage capacity estimates that account for the dynamic nature of subsurface environments.

At DTU Offshore, we leverage our expertise in advanced reservoir modeling and geomechanics to address this challenge. Using THMC (Thermal, Hydraulic, Mechanical, and Chemical) modeling, we analyze how subsurface systems respond to the simultaneous interactions of multiple physical processes. These interactions include:

- Temperature: Influencing chemistry and fluid viscosity

- Chemistry: Altering porosity and permeability, which affects fluid flow

- Fluid Pressure: Impacting mechanical stresses

- Mechanical Deformation: Changing fluid flow pathways

A solid understanding of the dynamic behavior of the entire aquifer system - where multiple CO2 storage sites and other subsurface activities share the same formation - is essential to prevent conflicts between future “neighbors.” When CO2 is injected, the pressure front moves significantly faster through the saline aquifer than the CO2 plume itself, making interference between structures both expected and necessary to understand.

The timing, scale, and operational details of each CO2 storage project, along with other subsurface activities, determine how these systems will interact. Proper coordination is therefore critical to preventing future disputes.

It is important to dynamically simulate different injection scenarios and to model the effects of water back-production. Here, experience from advanced reservoir modelling as well as the offshore produced-water management provides valuable insight.

Monitoring of CO2 injection is key for public acceptance of a CO₂ storage site, therefore when injecting CO2 into the subsurface integrity must be monitored.

There is a lack of reliable and cost-effective monitoring tools for offshore storage sites. DTU Offshore is developing various types of sensors in collaboration with the industry ranging from single point sensors which can be deployed stationary or on a moving remotely operated vehicle (ROV), and sensor networks to cover a larger area.

Get more insights

Subsurface CO2 storage could affect the marine environment in the unlikely event of a leak. Establishing a pre-injection environmental baseline is therefore essential. Such a baseline can also be utilized to understand the collected monitoring data. Ongoing research is developing a toolbox to support effective environmental baselining of CO2 storage sites.

If a leak occurs, the gas reaching the seabed is unlikely to be pure CO2. Injected CO₂, containing impurities, reacts chemically and biologically with surrounding fluids - and continues to interact with formations as it migrates toward the seabed.

Ongoing research aims to determine the composition of potential CO2 leaks and their effects on the seabed’s microbial environment.

Get more insights

Research is ongoing to develop software that estimates energy consumption across CCS value chains, linking European emitters with storage sites and accounting for different capture and transport methods. The software includes various capture methods, depending on the flue gas origin, and various transport methods.

When CO2 is captured, it will include impurities. Researchers at DTU Offshore is working on understanding the impact of these impurities on the reservoir integrity and injectivity. This knowledge needs to be linked with the impact of the impurities on the transport part of the value chain to understand the overall optimal cleaning of the CO2.

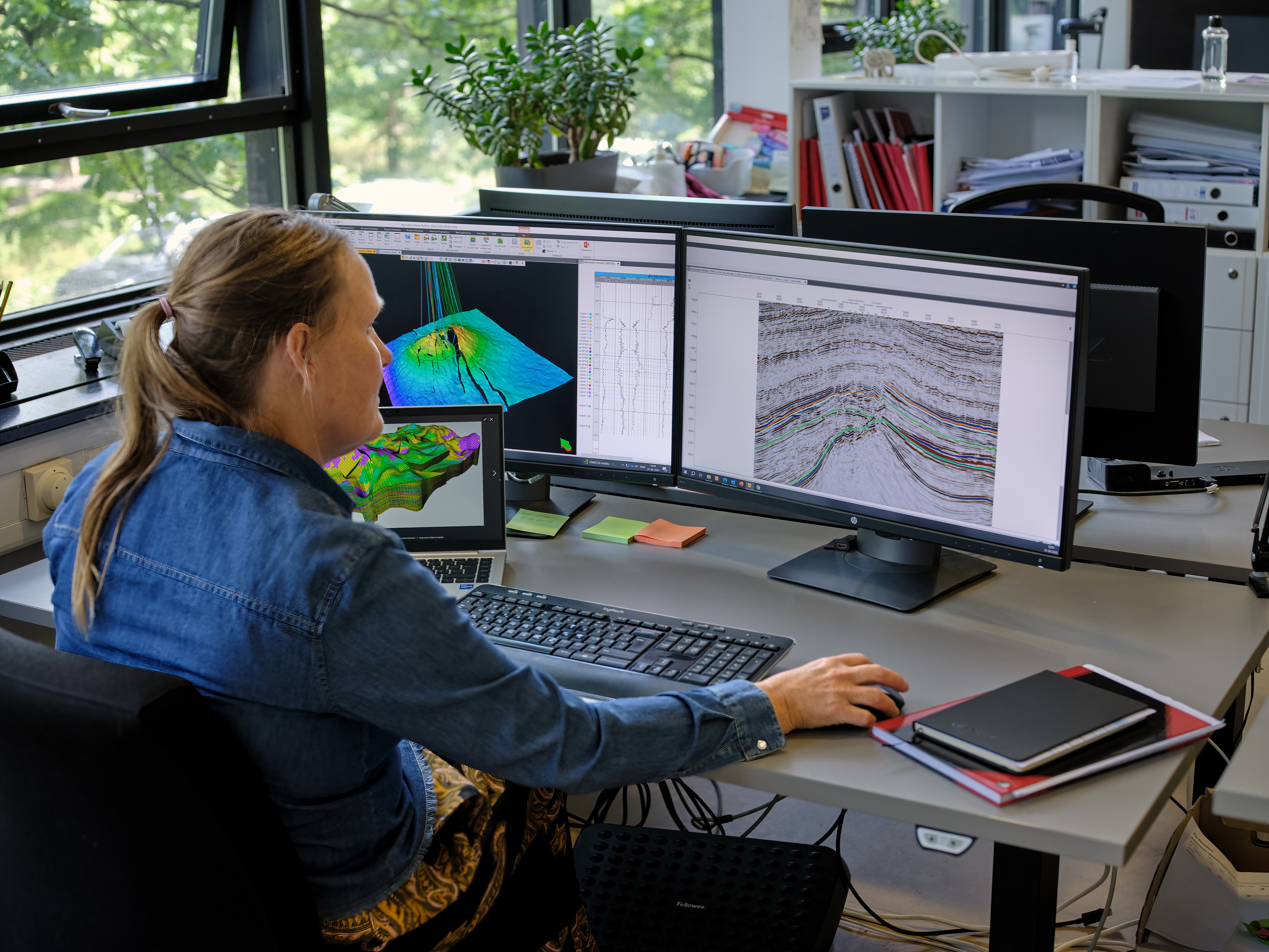

Deep knowledge about the subsurface is essential in succeeding with the energy transition.

Leveraging deep subsurface expertise, strong industry ties, and cross-disciplinary collaboration, we provide practical solutions for CO2 storage challenges.

DTU Offshore employs professionals with many years of industry experience. This is playing a significant role in our ability to ensure industry alignment and to implement research results in the industry.

Our team can provide support on various aspects related to geology, geophysics, geomodelling, and dynamic reservoir simulation.

The combination of subsurface expertise, research capabilities and lab facilities under the same roof has led to a unique collaboration model that stimulates application-oriented research while lowering the threshold to industry implementation.

DTU Offshore's subsurface expertise is being deployed to address multiple technological challenges:

- Geological and dynamic modelling of the subsurface

- Novel approaches to model rock compaction, reservoir souring, and the impact of injecting modified seawater on recovery

- Risk and uncertainty assessment

- Overburden assessment

- Monitoring techniques

Our knowledge and capabilities may also be used to provide feedback on the development of regulations and standards related to offshore operations, emphasizing environmentally responsible practices and technology adoption and enhance efforts to engage with and inform the public.

DTU Offshore also seeks to forge deeper international collaborations and partnerships to further enhance knowledge sharing, with a focus on education and application by the CCS industry.

Research is ongoing to develop software that estimates energy consumption across CCS value chains, linking European emitters with storage sites and accounting for different capture and transport methods. The software includes various capture methods, depending on the flue gas origin, and various transport methods.

The offshore area will play a key role in the energy transition, in both energy generation and storage. Research is exploring whether residual hydrocarbons in depleted reservoirs can be converted to hydrogen via microbial processes.

If successful this would mean that the existing installations might produce hydrogen instead of hydrocarbons, which e.g. could be used to decarbonize offshore CO2 storage facilities. Another research project is looking into whether CO2 hydrates can be used for temporary storage of excess energy.

Read more about activities regarding CO₂ storage

Contact

Charlotte Nørgaard Larsen New Projects Director Mobile: +45 93511536 clarsen@dtu.dk

Birgitte Dalsgaard Larsen Geoscience Advisor Mobile: +4593511836 blarsen@dtu.dk